- Alcohol

A World of Trusted Brands

SUPERIOR INDUSTRIES LIMITED

Superior Industries Limited, a pioneer name in the manufacturing of potable alcohol / Industrial Alcohol, having their distillery unit at 6th KM milestone, Rampur Road, Clutter Buck Ganj, Bareilly (U.P.) – 243502, has its registered office at plot no.202/E-57, West Vinod Nagar, Near Shanti Marg, New Delhi – 110092 and Corporate Office at Superior House, 8C/1, Part B, Rajpur Road, Civil Lines, New Delhi – 110054. We are the producers of Potable Liquor/Ethanol/ENA/ Spl. Denatured spirits/DDGS and have extensive coverage in the states of Uttar Pradesh, Uttarakhand, Delhi, Haryana, Punjab, etc.

Distillery Unit

Our distillery unit at Bareilly is a 134 KLPD alcohol manufacturing plant based on molasses and grain, which operates on green fuel energy. It is commissioned with all new and latest technologies and produces the best quality alcohol and potable liquors & Industrial liquor with the capacity of 469.00 lacs litres annually. Although we supply Industrial Alcohol (Ethanol) to all the OMCs on PAN India basis to Oil manufacturing Companies: IOCL, HPCL, BPCL, Reliance and Nayara Energy, and sizeable quantities to the various chemical industries as well as for their premier chemical brands, supplying domestically and globally.

SIL has achieved a gross total turnover of more than Rs. 1,800 Crores during FY 2023-2024 in comparison to Rs. 1,600 Crores approx. in the previous year. In the year 2024-25, the company is projecting to achieve a turnover of Rs. 2,000 Crores (Approx.). Superior Industries Ltd. is also planning to install an additional 60 KLPD grain plant, which will further increase the production capacity of potable liquor to 20,000 cases per day to enhance the Gross turnover of the company to the tune of Rs. 3,000 Crores (approx.) by 2025.

- Brands

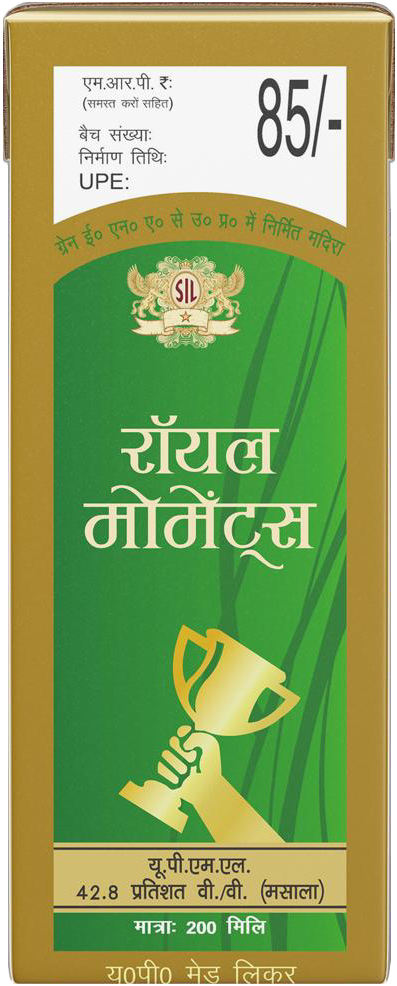

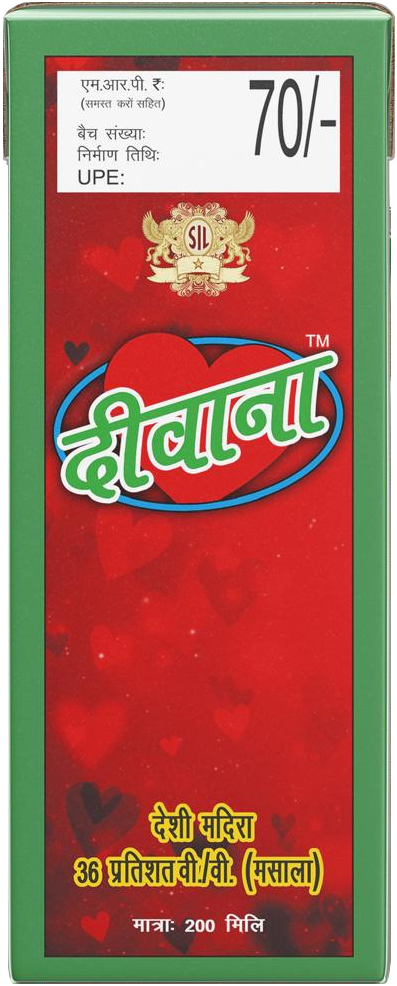

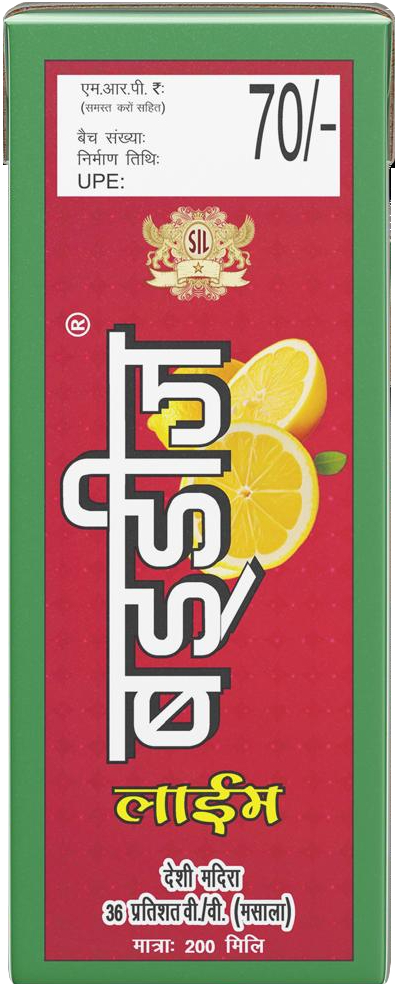

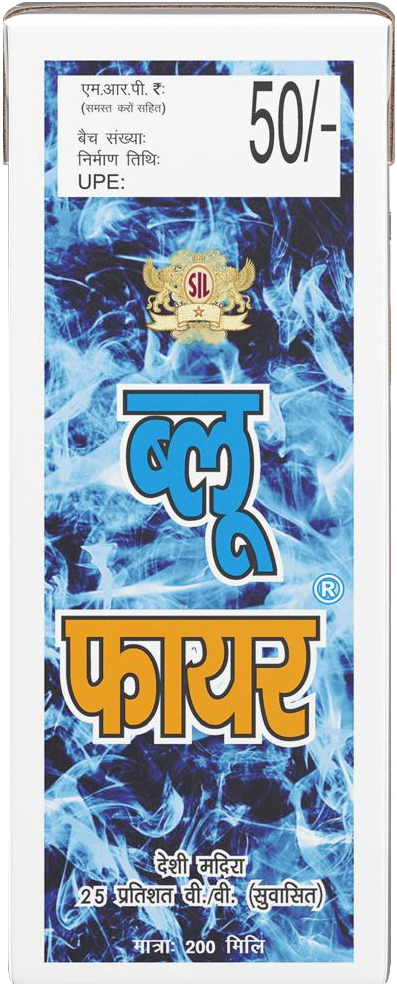

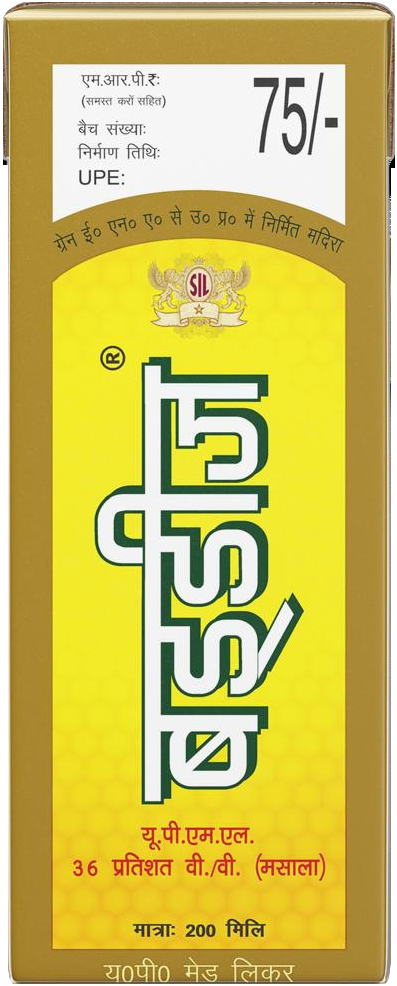

Superior has an entire gamut of Country Liquor Brands

which have a diverse customer base and notable amongst them are Soldier, Soldier Gold, Deewana, Babbar Sher Mirinda, Blue Fire, Angoori, Buddys, Buddys Lime, Royal Moments, etc. These brands are market leaders in their respective areas and are widely recognised by the market.

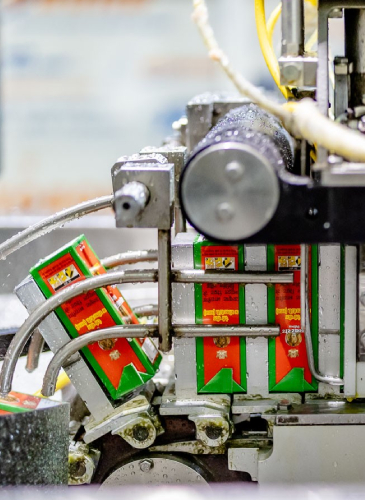

Superior has installed seven Aseptic filling machines that work round the clock to cater to the market demand for its products on a day-to-day basis.

Superior has also successfully launched IMFL brands under the brand names of Royal Antique, Golden Star, Oak Wood Whiskey, Royal Brigade, Lal Kaptan, Russian Eagle and has expanded its presence in Delhi region.

Life at Superior Industries Ltd.

Superior Industries Ltd. offers a comfortable work-life balance, supported by flexible working hours for employees. High employee morale stems from proactive management that values feedback and promptly addresses concerns at all levels. The organization fosters a goal-oriented work environment that encourages learning, growth, and collaboration. Many employees have long tenures of 15–20 years, reflecting the high satisfaction and positive workplace culture at Superior Industries.

Employee Strength

Superior Industries Limited, Bareilly, employs approximately 240 personnel across various departments, including Production (Molasses & Grain), Engineering, Commercial, Bottling Operations, Finance, HR, and Quality Control (QC). Additionally, the bottling operations and other tasks require a significant workforce of 350–400 contractual workers, depending on operational needs.

The company fosters a supportive and collaborative working environment, emphasizing professionalism and practicality to facilitate efficient large-scale manufacturing operations.

The management at Superior Industry has consistently stayed updated with the latest trends in the liquor market, equipping their plants with cutting-edge technology to achieve peak production efficiency. Over the past two decades, the company has transformed into a major industry player through relentless hard work, strategic leadership, and an unwavering commitment to excellence in the alcohol sector.

Manufacturing

The distillation plant operates using both grain and molasses as raw materials. Molasses is sourced from sugar mills, while the grain-based plant utilizes broken rice (damaged food grains) and maize. The grain plant’s entire ethanol production is supplied to oil manufacturing companies for blending with petrol, supporting the Government of India’s ambitious ethanol blending program aimed at reducing greenhouse gas emissions and dependence on fossil fuels.

In addition to ethanol, the company produces Extra Neutral Alcohol (ENA), which is supplied to leading liquor manufacturers, including ABD, Modi, ADS Spirits, and other prominent industry players.

The company boasts an annual production capacity of 46.9 million liters, utilizing feedstock such as cane molasses and various grains, including rice and maize. Superior also has the capability to produce potable liquor, offering packaging options in PET bottles, aseptic brick packs, and glass containers.

Sustainability

The sustainability of an industry relies on the growth of its products across diverse verticals, and Superior is fully aligned with these growth opportunities. Ethanol blending has emerged as a significant driver for ethanol manufacturers in India, with the country making rapid progress toward achieving a 20% ethanol blending target under the leadership of Prime Minister Shri Narendra Modi.

This shift reduces reliance on fossil fuels, steering vehicles towards ethanol-blended fuel—a major milestone in lowering emissions of harmful gases such as carbon monoxide, sulfur dioxide, and other carcinogenic compounds. This transition underscores a global commitment to advancing green fuel development and sustainable energy solutions.

According to growth estimates, India will require approximately 13.5 billion liters of ethanol annually by 2025–26. This rising demand provides significant impetus for the ethanol industry to thrive and ensures its long-term sustainability.

In addition to ethanol, the potable liquor industry has experienced remarkable growth, particularly in Uttar Pradesh, where it has expanded exponentially over the past six years. This sector has become a significant revenue generator for both the state and the industry. With an annual growth rate of 10–15%, according to conservative estimates, the liquor industry demonstrates robust sustainability and promising potential for continued development.

- Mission & Vision

Mission

We work together with makers in the industry to enhance the meaning of our stories. We are driven to create meaningful change for our clients, our community partners, and ourselves.

VISION

To serve our customers better, to always be relevant in their lives, and to form lifelong relationships.

Community

Superior has been actively engaging in community development initiatives in the areas surrounding its factory. These efforts include constructing public conveniences such as toilets and distributing blankets to those in need during winter. The company also focuses on creating employment opportunities for local residents, aligning with its ambitious growth plans and fostering a stronger connection with the community.

- Careers

We nurture the talents Capable of aligning

With our robust growth trajectory, we are committed to providing guidance and mentorship to groom successful candidates who will join us in achieving our business objectives. We welcome talent from both similar and diverse industries, fostering the integration of best practices to drive growth within our ecosystem.

Our team includes a roster of accomplished professionals who have significantly contributed to our progress and goodwill. Superior offers an equal platform for all employees to assess challenges, propose solutions, and share insights. The most effective suggestions are recognized and implemented by our Managing Committee.

We are dedicated to offering an exceptional foundation for both new and long-standing associates, ensuring their success and growth alongside the company.

Waste Management

The safe disposal of distillery waste is the key to achieving business goals without damaging the environment. It is a commitment towards the society that we uphold the basic principle of peaceful coexistence of business with nature and we fully abide by this commitment towards our customers, stakeholders, employees and community.

We, at Superior are fully committed towards maintaining the above, and we reaffirm that no pollution goes on to contaminate air, water and land.

We are a ZLD (Zero liquid discharge) unit having full compliance, through latest pollution control equipment like Slop fired incineration boiler which converts the highly corrosive distillery spent wash effluent to boiler fuel thus eliminating the escape of the harmful pollutants to water streams.

Boiler flue gases and other harmful gases are passed through the ESP to precipitate the carbons and other carcinogenic particles and prevent escape into the atmosphere.